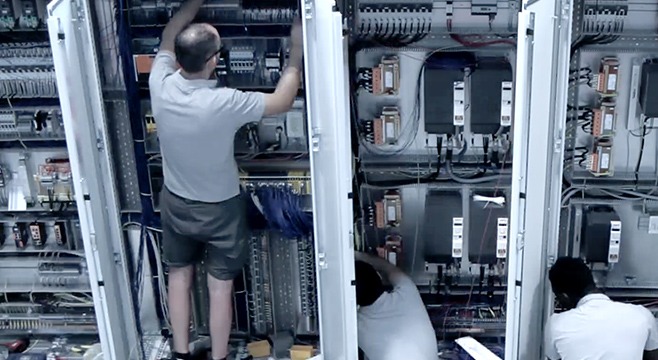

In Cubi Srl our main focus is on long-term customer satisfaction and that is why we have a department dedicated to electrical panels, with a team made up of experienced designers and technicians and skilled workers able to build the panel from 0.

The technicians are professionals in charge of designing the electrical panel on the computer, and of creating the plans necessary to create all the components in the workshop.

Subsequently, the project manager will take care of the installation and connections with the necessary checks, adjusting the related wiring on site.

We not only deal with the installation of new panels, but also with the revamping and overhaul of electrical panels and systems already in place.

As regards the programming of PLCs or BMS systems, we always offer the customer the possibility of having a connection to the PLC via the customer’s data network to remotely access the PLC to check the problem and solve it without having to intervene on site, thus reducing the lead time on any malfunctions or making small changes to the programming at the customer’s request.

Cubi Srl, a company from Verona, deals with studying, installing or maintaining electrical systems and electrical panels for large industrial companies, healthcare facilities, accommodation and sports facilities. In particular, we are engaged in services to the public administration, trade fairs and shopping centers.

Example of electrical panel

P. Pederzoli Hospital – Proven Nursing Home

To support the amount of energy necessary for the proper functioning of the hospital, we have installed n. 4 medium voltage transformer cabins, and a 1MW cogenerator plant capable of guaranteeing electric current when it fails due to natural causes or electrical faults.

Giovanni Rana pasta factory

We have created the electrical panel of the entire structure of the Pastificio Rana with the aim of developing and enhancing the production department to the maximum, thanks to technologies capable of intelligently distributing the amount of energy needed, improving energy efficiency and safety of the plant.

An electrical panel for the food sector is made up of specific and sophisticated technologies capable of automating the various processes and guaranteeing energy continuity, and last but not least, it provides real-time diagnostics capable of having a 360-degree control of performance.

Cleaner and more efficient electrical panels

The advantages in building, or rather reconstructing an industrial panel are many. First, it means making the site safer from overloaded circuits or electrical fires, as well as saving money, making the site more environmentally friendly and saving time. But not only that, it also inevitably improves the competitiveness of the company as it has clean energy, with cutting-edge and updated systems.

In an era like this, where you want to change course regarding the use of energy from renewable sources, even electrical panels must comply with standards and systems that allow for high energy efficiency.

Cubi Srl is able to deal with the design, production and certification of all electrical panels, wiring and control of functionality by means of special tools as required by the CEI EN 61439 standards.

The company follows the customer from the preliminary study to the testing phases, up to the next scheduled maintenance.

The steps to follow are:

Cubi Srl deals with the design and installation of electrical panels for the automation of production processes via PLC of the main manufacturers or with KNX technology for the management and control of buildings and homes. The programming of PLCs and devices with KNX technology is developed by our programmers. The systems can be implemented with an electricity management system to assign costs or for the control and management of utilities.

The executives can be certified: